Texas Teens Turn Sound Waves Into a Weapon Against Microplastics

Two 17-year-olds from The Woodlands, Texas have built a pocket-size device that uses high-frequency sound to pull toxic microplastics out of flowing water — and it just earned them $50,000 at the Regeneron International Science and Engineering Fair. Their project also topped the Earth & Environmental Sciences category.

Those wins, detailed by Business Insider and confirmed by FOX 26 Houston, push a lab-tested idea toward real-world water protection.

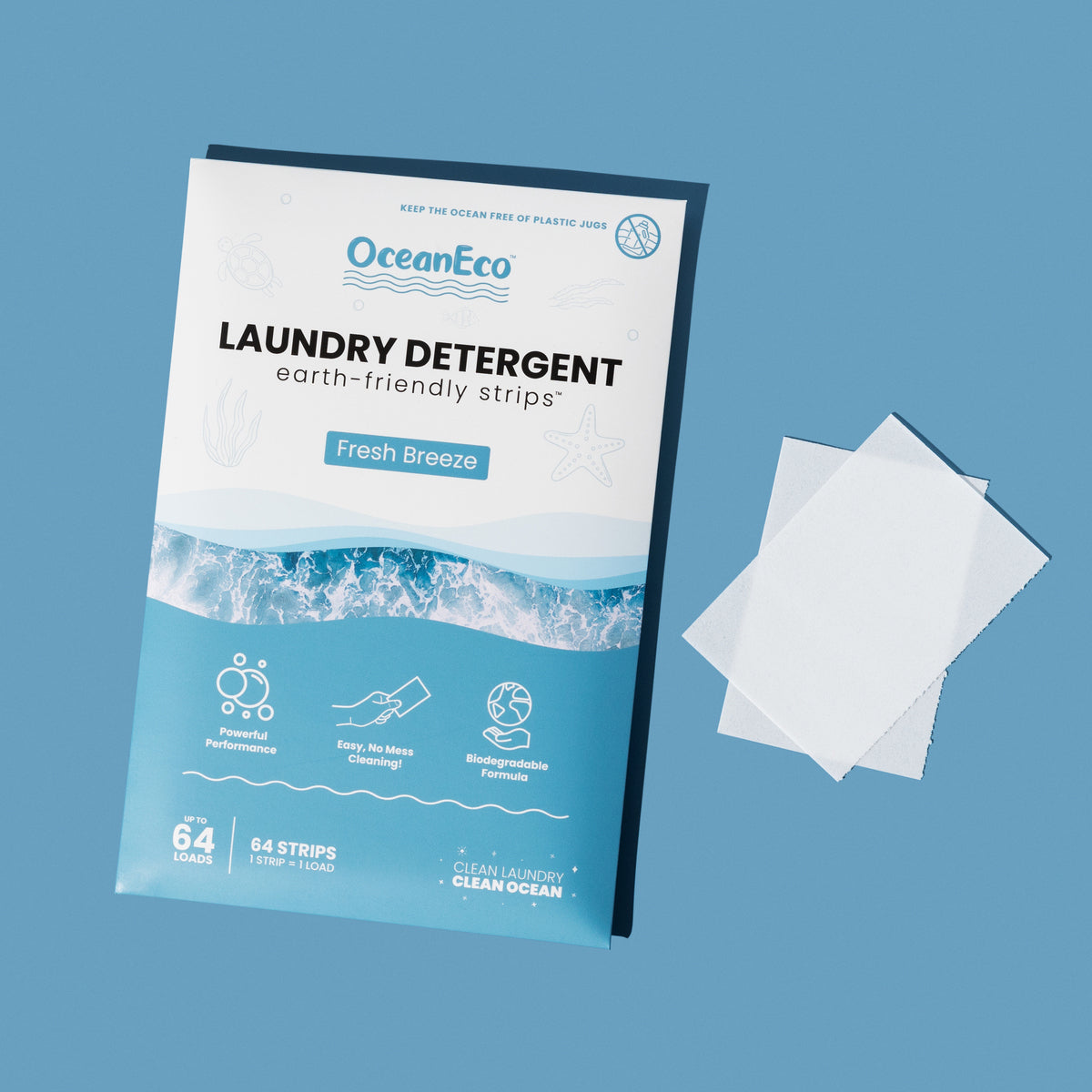

Two Texas teens invented a device that filters toxic microplastics from water.

A Small Device With Big Ambitions

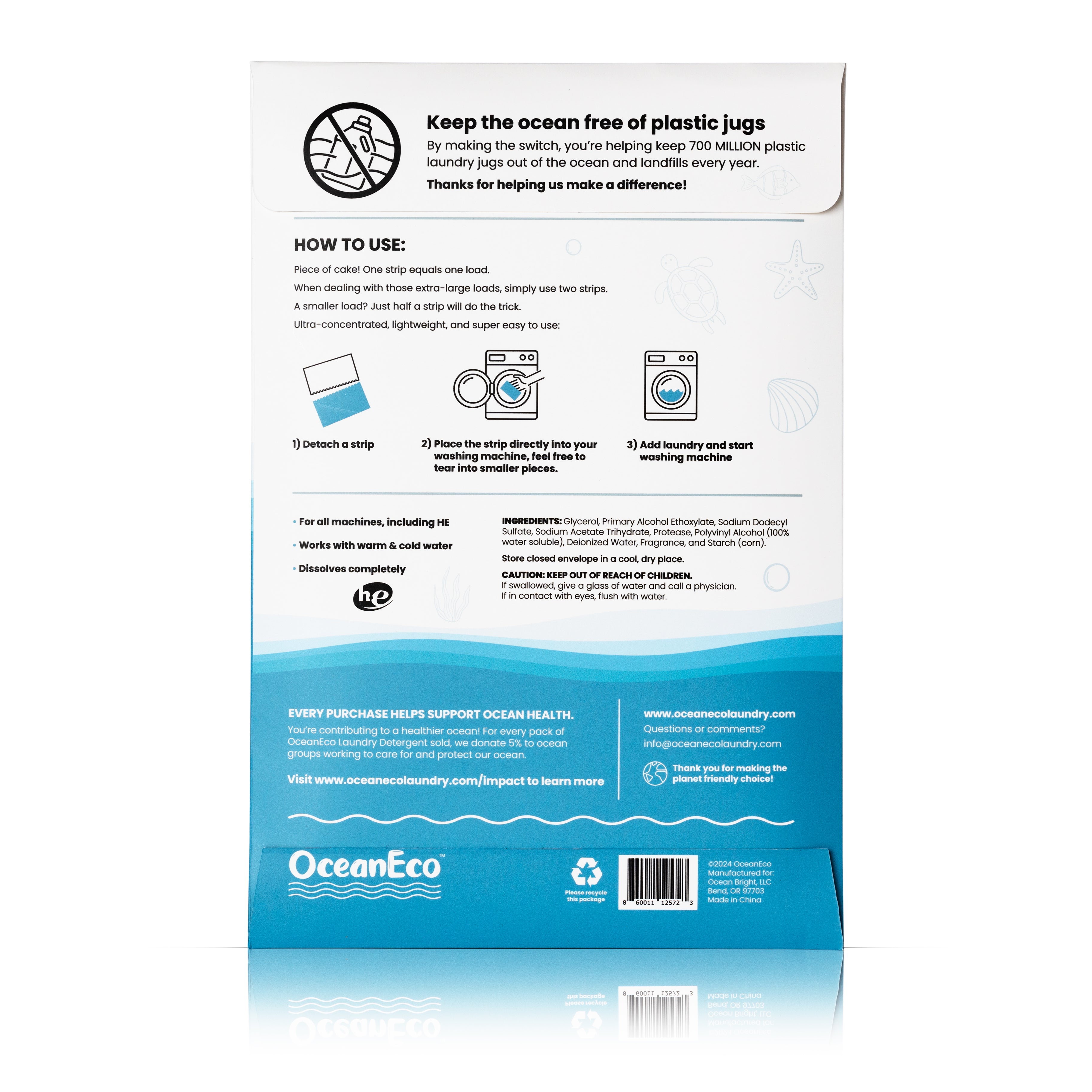

The invention is roughly the size of a pen. Inside, a tube and two ultrasound transducer stations create a pressure field that holds back microplastic particles while letting water move on. In single-pass tests, the setup removed about 84% to 94% of particles such as polyurethane, polystyrene, and polyethylene, according to Business Insider and Good News Network.

The invention uses ultrasonic sound waves instead of chemicals or costly filters.

Why It Matters Now

Microplastics are turning up from deep ocean trenches to household taps. Traditional removal options can be costly, slow, or reliant on chemicals that add new problems. Physical filters clog. Biological routes often move too slowly for scale.

The students targeted those gaps after learning that local facilities did not have microplastic controls in place — a reflection of the current regulatory picture — as reported by Wonderful Engineering.

How the ‘Wall of Sound’ Works

Unlike approaches that clump particles with chemicals or concentrate them for later capture, this design uses acoustic pressure to block microplastics directly in the flow path. The result: cleaner outflow without added reagents. Good News Network notes that this simplified geometry helps the device punch above its size.

The device is no bigger than a pen but shows big promise.

From Laundry Rooms to Treatment Plants

The pair see a pathway from benchtop to broad deployment. Water utilities, industrial textile facilities, and rural systems could integrate acoustic filtration to cut plastic loads before discharge, FOX 26 Houston reports.

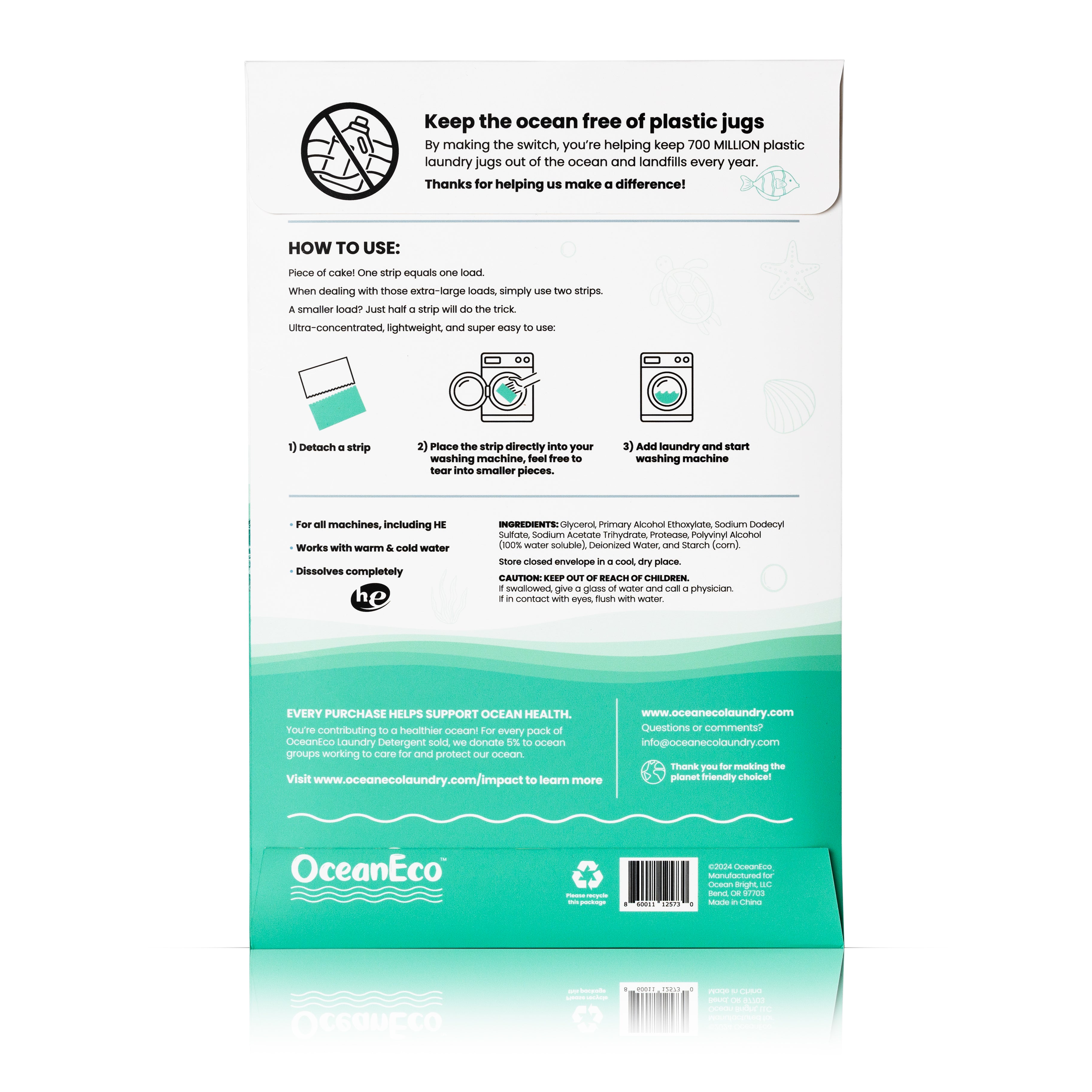

There’s a household angle too: laundry cycles shed fibers that account for a large share of primary microplastics. As Planet Ark explains, capturing those particles at the machine could prevent a major source of pollution before it hits drains.

Biological solutions break down plastics too slowly to be useful at scale.

Scaling Up

The prize money from this contest can fund better instrumentation, larger prototypes, and tougher trials. The students are already planning the next phase, according to Planet Ark. The technical direction is clear: keep the design simple, maintain high capture rates, and prove throughput. As first steps go, this one is strong — a compact system targeting a sprawling threat.