Fishing Waste Becomes Ocean Innovation, As Discarded Nets Are Turned Into Everyday Goods

Ian Falconer walks the Newlyn harbor and sees opportunity where others see hazard. The Cornwall entrepreneur founded OrCA to turn discarded nylon fishing nets into material for 3D printing, cutting waste that harms wildlife while creating products people can use, The Guardian reports.

Each year, vast amounts of fishing gear are abandoned or dumped, with real consequences for marine life. A Plymouth Marine Laboratory ecologist told the paper that “ghost gear” is among the most serious threats in the sea, and that credible recycling schemes help keep it out of landfills and waters, the Guardian notes.

Ghost nets continue killing wildlife long after fishers abandon them.

A Kitchen Test That Became A Micro-Factory

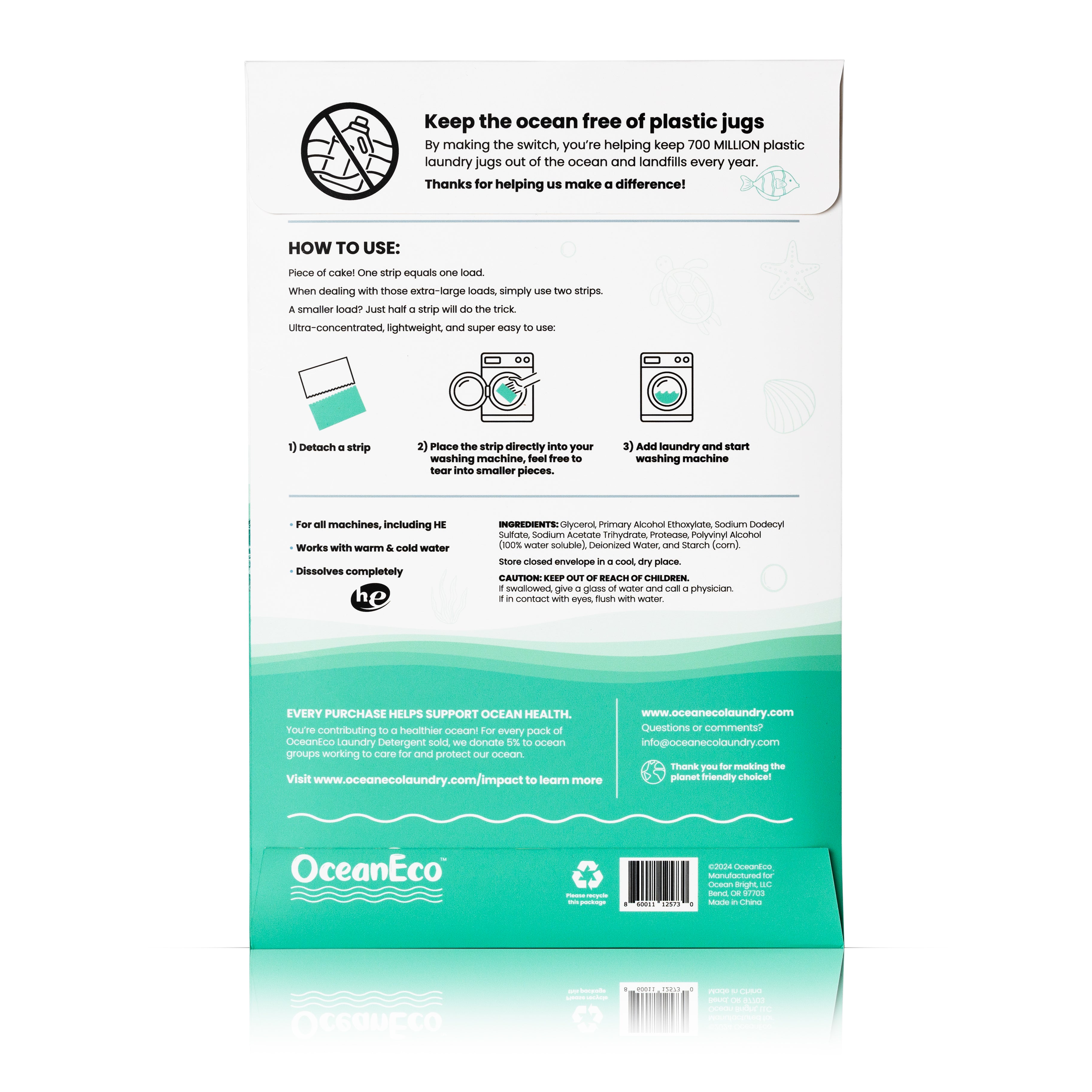

Falconer started small. He persuaded the local harbor master to hand over a few worn nets, then proved at home that nylon could be shredded, cleaned, melted, and extruded into new filament. That experiment grew into a patented “micro-factory” capable of processing more than 20 kilograms of nets an hour, according to the Taipei Times. He says the carbon impact of his process is under 3% of making virgin nylon.

When Waste Becomes Valuable

The shredded nets emerge as blue-green pellets that go to 3D printers or injection-molding lines for everyday items—sunglasses, lamps, even motorbike parts—reducing demand for new plastic. According to the Guardian, his premium blend, mixing recycled nylon with waste carbon fiber from automotive and aerospace offcuts, can command up to $46,900 per ton,. That’s a dramatic reversal for material that once cost fishers roughly $670 per ton to dispose of, OneGreenPlanet reports.

Discarded nets entangle turtles, dolphins, seabirds, and reef life.

Real Demand, Real Climate Benefits

Global brands—including Ford, Mercedes-Benz, Philips, and L’Oréal—are already buying OrCA’s recycled material to hit sustainability targets while lowering plastic footprints, according to [t](https://www.onegreenplanet.org/news/this-man-is-turning-ocean-waste-into-wealth-on-the-cornish-coast/)he Taipei Times. The push aligns with European rules nudging automakers toward at least 20% recycled plastic by 2035. Lower-carbon nylon also cuts lifecycle emissions tied to gear, manufacturing, and disposal.

Scaling For Oceans—and Communities

Nylon monofilament net production is climbing, while traditional nylon recycling capacity remains constrained and mostly devoted to carpets and textiles. Falconer’s answer is modular: ship a containerized micro-factory to any harbor that wants it. The plug-and-play units, priced around $500,000 if built in the UK, could turn a costly hazard into a local revenue stream in ports across Africa, South America, and Asia, OneGreenPlanet reports. The aim is simple: remove nets before they entangle turtles, dolphins, seabirds, and reef systems, and give coastal communities a stake in prevention.

Recycling nets removes a persistent hazard from coastal waters.

Why It Matters Now

Old nets don’t just disappear. They drift. They snag. They keep killing. By turning them into durable raw material with real market pull, OrCA links cleanup to commerce. That linkage can keep gear off beaches and out of the blue. And it gives fishers and manufacturers a clear alternative that pays.